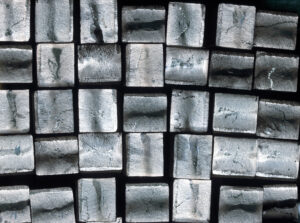

A Short Guide to T304 T303 T316 Stainless Steel Alloys

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

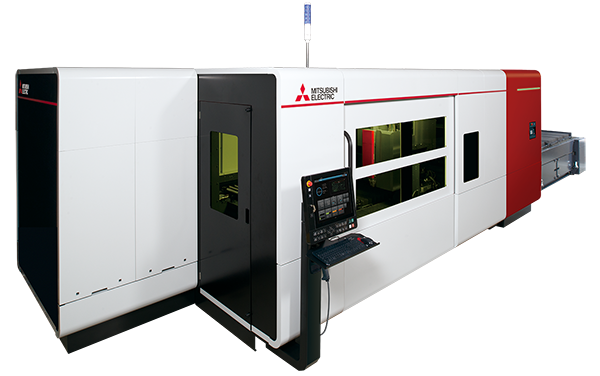

When it comes to offering the best in precision and power, the Mitsubishi 3015 GX-F60 Fiber Optic Laser Cutter stands out as a true game-changer. This remarkable machine is not just a tool. It’s a technological marvel that caters to the needs of industries that demand nothing but the best in precision cutting.

One of the key attributes that sets the Mitsubishi 3015 GX-F60 apart from other laser cutters is its ability to process a wide range of materials with astonishing precision. Whether you’re working with metals or nonmetals like acrylic, wood, or glass, this laser cutter can handle it all. Its versatility extends to thicknesses as well.

Our Mitsubishi 3015 fiber optic laser will cut up to 1” thick mild steel, ¾” thick stainless steel, and ½” thick aluminum.

At the heart of the Mitsubishi 3015 GX-F60 is its cutting-edge fiber optic laser technology. This advanced system utilizes high-powered beams generated through fiber optic cables, resulting in a focused, intense cutting force.

The GX-F60 utilizes the Mitsubishi Advanced Fiber Laser Oscillator, cutting at 6000 watts with a beam kerf of approximately .004”.

Unlike conventional CO2 lasers, fiber optic lasers are more energy-efficient, faster, and offer exceptional cut quality. This translates into cleaner part edges, minimal heat-affected zones, and reduced material waste. This also translates into reduced operating costs. In turn, Alcobra is able to pass that savings on to customers and gain a competitive edge in quality, speed, and cost.

The increased speed of fiber optic lasers provides an additional advantage: minimal distortion and warping of the cut materials. Parts are typically cool enough to touch right after cutting.

The precision offered by the Mitsubishi 3015 GX-F60 allows us to cut extremely complex designs with ease. Whether you’re creating delicate jewelry pieces or building aerospace components with demanding geometries, the GX-F60 offers supreme quality. It is an invaluable tool for industries where high tolerances are an important detail.

While laser cutting technology continues to evolve, the Mitsubishi 3015 GX-F60 stands out in a crowded field of cutting machines. Here’s how:

Laser cutting with the Mitsubishi 3015 GX-F60 generates minimal waste, reducing environmental impact and material costs. This is in contrast to water jetting, which produces significant waste in the form of abrasive particles and water runoff.

Additionally, with a smaller beam kerf of around .004″, parts can be nested very tightly within the sheet. This means more parts per square foot and less material in the recycle bin. Since Alcobra sells sheet and plate by the square foot, our customers are now gaining more parts for the same cost they would pay for parts cut on older CO2 lasers. Better yet, the quality of the parts cut by the Mitsubishi is vastly more superior than parts cut by other lasers. The Mitsubishi 3015 GX-F60 offers an absolute win/win scenario for our customers and Alcobra.

Repeatability is a very important detail in manufacturing. The GX-F60 offers unmatched accuracy and consistency, with ±0.00039” (0.0099 mm) repeatability.

Artificial intelligence is a branch of computer science that automates intelligent behavior and machine learning. This means the machine itself can learn from data and adjust performance without human intervention. The Mitsubishi 3015 GX-F60 will automatically recall job parameters it records when similar jobs, materials, and parts are being processed. This helps ensure repeatability for every job.

Laser cutting is generally faster than water jetting, ensuring shorter production times and quicker turnaround. Travel speed is up to 6700″ per minute, depending on the material being cut. Since Alcobra bills laser cutting at an hourly rate, the Mitsubishi 3015 GX-F60 allows us to offer more parts to customers for the same hourly rate they would pay for parts cut on other machines such as a water jet or CO2 laser cutter.

In conclusion, the Mitsubishi 3015 GX-F60 Fiber Optic Laser Cutter is a true marvel of precision manufacturing. The machine’s ability to cut a wide range of materials with unparalleled accuracy and efficiency sets it apart. When precision is non-negotiable, this machine is your ticket to superior parts and improved productivity.

With the Mitsubishi 3015 GX-F60, you’re not just cutting materials; you’re sculpting them with precision, speed, and finesse. You’re also saving considerable time and money.

Please contact us with any questions about your laser cutting needs. We are happy to assist with any current or future project at your company. For other details on our processing capabilities, click here.

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

As Q4 2025 unfolds, the global metals and steel industry is navigating a landscape of cautious growth amid persistent challenges. For U.S. steel suppliers, this means a pivotal moment to