A Short Guide to T304 T303 T316 Stainless Steel Alloys

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

The versatility of stainless steel makes it a cornerstone for manufacturing sectors across the globe. This is why Alcobra keeps many types of stainless steel alloys in stock, and why we are known for our extensive range of stainless products.

Manufacturing companies depend heavily on access to stainless steel for a variety of applications. Even your home and office is full of gadgets and appliances that utilize stainless steel.

To meet the high demand for this material, stainless steel mills have developed a wide variety of specific stainless alloys. Each alloy presents its own unique set of benefits and specialities. Below is a brief explanation of common stainless steel alloys and their uses.

T303 stainless steel is an austenitic alloy known for its excellent machinability. This is achieved by adding sulfur. First, this enhancement makes T303 ideal for high-speed machining processes, a crucial factor in precision parts manufacturing. T303 is commonly used for parts such as fittings, fasteners, gears, shafts, and other screw machine parts. Second, machinists prefer the T303 alloy because it is easy to source. It is also not very hard on tooling during machining. This means the machinist will not burn or wear out tooling as quickly as machining other alloys.

One of the tradeoffs of T303 versus other alloys is its corrosion resistance. It is generally considered to be less corrosion-resistant than other alloys such as T304 or T316. This means it is not used in applications where harsh corrosive environments are common.

The versatility of stainless steel is perhaps best exemplified by T304. It is the most widely-used and most common stainless steel alloy. Its well-balanced combination of corrosion resistance, durability, and affordability makes it a staple in a myriad of applications. Hence, T304 is used throughout all sorts of food service, dairy, brewing, and commercial kitchen applications. This is due to the alloy’s resistance to oxidation, easy availability, and ease of welding and fabrication properties. Any stainless steel items in your house are likely T304.

When superior corrosion resistance is required, T316 stainless steel is the alloy of choice. Enhanced with 2-3% molybdenum, T316 exhibits exceptional resistance to chlorides and other industrial solvents. Thus, T316 is indispensable in salt-water environments, chemical processing, and pharmaceutical equipment. Additionally, the added strength and durability of T316 ensure longevity and reliability in applications exposed to harsh chemicals and saltwater. T316 is pivotal in protecting critical components from premature failure and costly maintenance.

T416 is a martensitic stainless steel characterized by its high strength and hardness. This added strength is achieved through heat treatment. Unlike austenitic steels, T416 contains higher carbon content and can be hardened significantly. Consequently, this makes T416 ideal for manufacturing parts that require superior wear resistance and mechanical strength.

Some applications of T416 include pump shafts, valve parts, and gears. Its machinability and ability to be hardened also make it a preferred material for precision instruments and cutting tools. However, T416’s corrosion resistance is lower than austenitic grades.

17-4 stainless steel offers a unique combination of strength, hardness, and corrosion resistance. This material is formulated with approximately 17% chromium and 4% nickel, with additional copper, niobium, and other trace elements. This stainless alloy is commonly used in aerospace, chemical, petrochemical, and food processing industries. This is due to its ability to maintain its mechanical properties at elevated temperatures.

Common uses include turbine blades, nuclear reactor components, and high-performance marine parts. Moreover, these applications benefits from the alloy’s robust performance under stress and corrosive conditions.

In conclusion, the versatility of stainless steel alloys, from T303 to 17-4, highlights the material’s adaptability to various needs. Whether the requirement is for machinability, corrosion resistance, strength, or durability, there is a stainless steel alloy designed for your application.

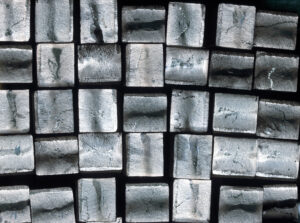

Alcobra stocks a wide variety of stainless steel items. This includes stainless steel round bar, angle, flat bar, sheet, plate, channel, and tubing. Before placing your next order, ask our salespeople what stainless alloys might be right for your next project.

For more technical information regarding stainless steel, visit our stainless steel product guide here. Explore Alcobra’s extensive selection of stainless steel products here.

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

As Q4 2025 unfolds, the global metals and steel industry is navigating a landscape of cautious growth amid persistent challenges. For U.S. steel suppliers, this means a pivotal moment to