Reliable Metal Suppliers: Why Alcobra is Your One Stop Shop

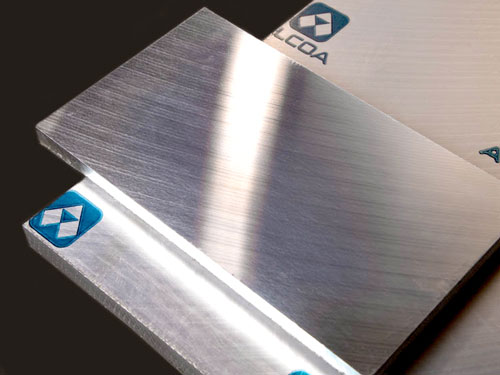

A Reliable Metal Supplier with a Vast Inventory At Alcobra Metals, we pride ourselves on being a reliable metal supplier with a comprehensive selection of materials. In fact, our inventory

The specialty metals industry is a cornerstone of the ever-evolving economic landscape in the United States. Many alloys, characterized by distinctive properties, play a crucial role in setting a foundation for many industries across the country. As such, access to these alloys is also crucial. A demand for products made in the USA is driving companies towards policies that require their raw materials to be domestically produced.

From aerospace components to medical devices, automotive parts, and infrastructure projects, these metals are what keep our economy running. As manufacturers seek to enhance their existing products and develop new ones, the demand for advanced alloys continues to grow.

Materials such as Nitronic 60 and TI6AL4V titanium are good examples of this continual pursuit of improvement. Other historical examples include: C954 aluminum bronze, 6061 aluminum, and 4130 chromoly. This American-driven pursuit of improvement fostered a symbiotic relationship between the metals industry and various manufacturing sectors in the US at least as far back as the early 20th century.

Consumers are increasingly recognizing the value of supporting local industries. These reasons are motivated in part by patriotism but also due to the assurance of higher quality products. This rise in demand for USA-made products has placed some added pressure on the metals industry. Currently, many manufacturers aggressively seek USA-made materials in order to produce goods that proudly carry the label of “Made in the USA.”

The metals industry’s impact on domestic manufacturing extends beyond consumer sentiment. It contributes significantly to job creation, economic growth, and national security.

The metals industry in the United States offers a variety of stable, well-paying employment opportunities and career paths. According to the Bureau of Labor Statistics, the average hourly earnings for non-supervisory employees average around $25 per hour for an average of 40 hours of work per week. Some of the higher-paying non-supervisory roles include: cutting, punching, machine setting, inspection and testing, and furnace operators.

These roles rarely require higher education degrees, and often lead to rewarding and fulfilling careers. Careers in metals extend into sales, computer-aided design (CAD), purchasing, and other niche positions related to the industry. A robust and self-reliant manufacturing ecosystem ensures that the United States remains resilient in the face of global economic uncertainties.

In conclusion, the metals industry is a linchpin for supporting domestic manufacturing. Offering a diverse range of materials empowers industries to innovate and produce high-quality goods. As the demand for made-in-the-USA products rises, the metals sector will play an increasingly pivotal role in shaping the future of American manufacturing.

A Reliable Metal Supplier with a Vast Inventory At Alcobra Metals, we pride ourselves on being a reliable metal supplier with a comprehensive selection of materials. In fact, our inventory

A day to remember We would like to thank everyone who came to see us during our open house event on June 7. About 200 people popped by to enjoy