A Short Guide to T304 T303 T316 Stainless Steel Alloys

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

The COVID-19 pandemic disrupted industries and economies worldwide. Companies were pushed into re-thinking lean manufacturing principles and adapt to a “new normal.” Consequently, the manufacturing sector faced a unique set of challenges that pushed the concept of lean manufacturing to its limits.

In this blog post, we will briefly explore how the COVID-19 pandemic generally challenged the principles of lean manufacturing. We will also take a short look at how manufacturers adapted to these challenging times.

Lean manufacturing is a set of principles and practices aimed at optimizing production processes, reducing waste, and increasing efficiency. Central to this concept is the just-in-time (JIT) production system, which minimizes inventory, lowers costs, and enhances flexibility. The key elements of lean manufacturing include continuous improvement, waste reduction, efficient workflows, and high-quality products.

The COVID-19 pandemic brought some unique challenges that tested the resilience of lean manufacturing including:

Lockdowns, travel restrictions, and forced interruptions in trade led to supply chain disruptions. Manufacturers faced delays in receiving raw materials, components, and parts, making it difficult to maintain JIT production.

Many industries experienced significant fluctuations in demand as a result of the pandemic. Some products faced increased demand (e.g., medical equipment and cleaning supplies). Others experienced a sharp decline (e.g., automotive and non-essential consumer goods).

Manufacturers had to adapt and re-think lean manufacturing to navigate the challenges posed by the pandemic:

Relying on a single supplier for critical components or materials became a vulnerability during the pandemic. Many manufacturers started diversifying their supplier base to reduce the risk of supply chain disruptions.

Manufacturers had to invest in new safety measures, redesign layouts, and optimize workflows to ensure the safety of their workforce while maintaining productivity. This included adjusting production lines to accommodate social distancing.

In response to supply chain uncertainties, some companies started maintaining a buffer stock of critical components to mitigate the risk of stock-outs. This strategy allowed them to weather potential disruptions.

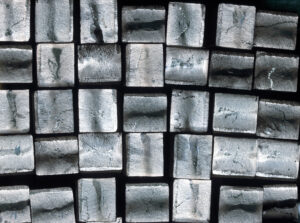

As a material distributor, Alcobra saw an immediate need to increase stock among our more popular lines such as aluminum and stainless steel items.

The pandemic accelerated the adoption of digital technologies and automation in manufacturing. These technologies helped manufacturers operate with reduced workforce capacity while maintaining production levels.

Some manufacturers repurposed their facilities to produce in-demand products. For example, automotive companies shifted to producing medical equipment. Flexibility and the ability to pivot quickly became essential.

The COVID-19 pandemic challenged the conventional principles of lean manufacturing. This forced companies to adapt and re-think their production workflows. In the face of supply chain disruptions, fluctuating demand, and safety measures, manufacturers demonstrated remarkable resilience and adaptability.

The lessons learned from this challenging period will likely lead to a more robust approach to lean manufacturing. Enterprises around the world will no doubt continue to optimize alternative processes while mitigating risks associated with an uncertain manufacturing landscape.

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

As Q4 2025 unfolds, the global metals and steel industry is navigating a landscape of cautious growth amid persistent challenges. For U.S. steel suppliers, this means a pivotal moment to