A Short Guide to T304 T303 T316 Stainless Steel Alloys

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

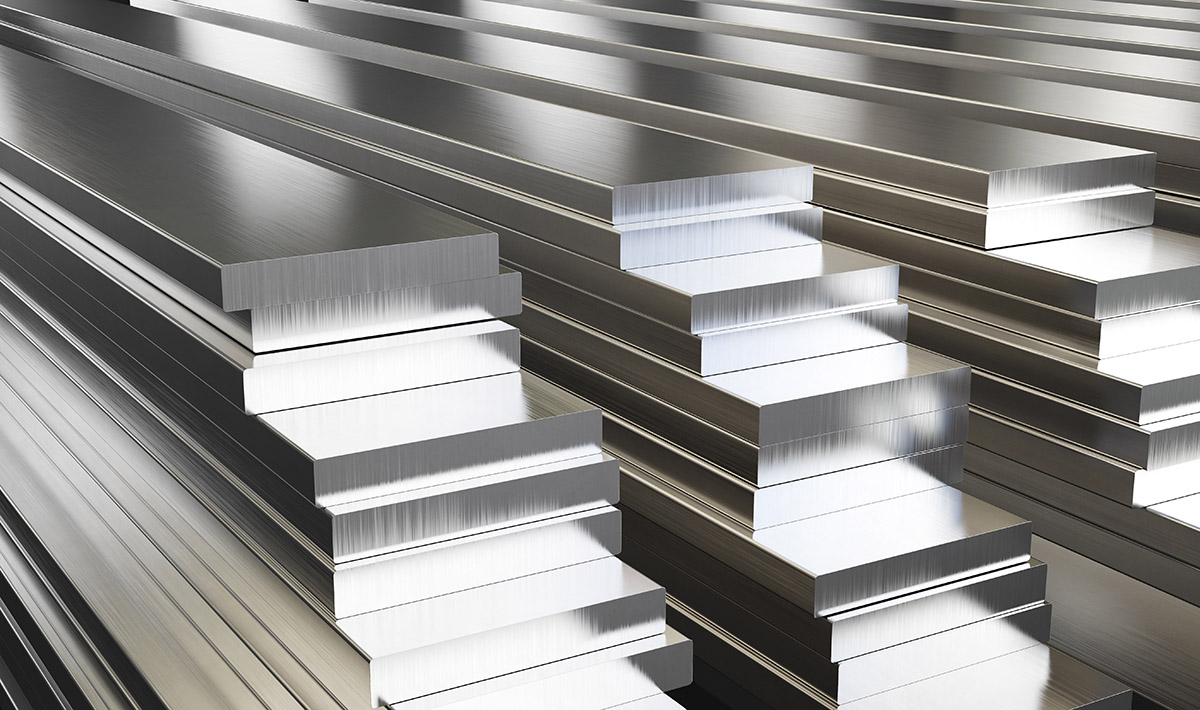

Aluminum alloys are widely used due to their exceptional strength, lightweight nature, and corrosion resistance. Two popular alloys in the aluminum family are 6061 and 6063.

While they may appear similar at first glance, these alloys possess distinct characteristics that make them suitable for different applications. Below are just a few of the dissimilarities between 6061 and 6063 aluminum alloys, along with typical applications and factors that generally influence customer preferences.

6061 aluminum alloy is renowned for its strength and excellent machinability. It contains magnesium and silicon as its primary alloying elements. With a higher strength-to-weight ratio than 6063, 6061 is commonly utilized in structural applications, such as aircraft and marine components, bike frames, automotive parts, and high-stress machinery.

One of the distinguishing characteristics of 6061 shapes is the radius on the inside corners of the profile. This further adds to the strength and rigidity of the material.

Its robustness and weldability make it an ideal choice for applications requiring strength and durability.

Additionally, 6061 aluminum can be easily anodized, providing enhanced surface protection and aesthetic appeal.

The 6063 aluminum alloy is highly valued for its exceptional extrudability, making it the go-to choice for many extruded profiles. It contains magnesium and silicon as well, with slightly lower amounts than 6061.

You can typically identify if a shape is extruded in 6063 by paying attention to the right angle on the inside corner of the material. This square, flat corner makes it much easier to use in architectural applications such as window and door frames and other ornamental purposes.

6063 aluminum can easily be shaped and bent without sacrificing structural integrity. This makes it a preferred option for intricate designs and aesthetics. From a manufacturing standpoint, 6063 aluminum is easier to extrude than 6061, so there is a much wider variety of profiles available.

When choosing between 6061 and 6063 aluminum alloys, customers should consider the specific requirements of their applications. If strength and robustness are crucial, 6061 is the superior choice. Its increased strength makes it suitable for load-bearing structures and high-stress environments.

On the other hand, customers seeking exceptional extrudability and formability should opt for 6063. Its versatility in achieving complex shapes and smooth finishes makes it ideal for architectural and decorative purposes.

For a more specific look at the different compositions of each alloy, click here.

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

As Q4 2025 unfolds, the global metals and steel industry is navigating a landscape of cautious growth amid persistent challenges. For U.S. steel suppliers, this means a pivotal moment to