CNC Machining

Alcobra metals holds the highest standards when it comes to machining your parts. We will work closely with you to specify tolerances, lead times, and can offer assistance in choosing the right material for your part and application.

CNC Machining Services With Precise, Fast Results

CNC (computer numerical control) machining is an automated, computer controlled process and forms the basis of many cutting edge manufacturing applications today. It works by taking your digital model and converting it into numbers. These numbers can then be thought of as coordinates for the lathe or milling equipment used to cut your part. This whole process means precision machining with faster production times and consistent results.

CNC Machining Services With Precise, Fast Results

We offer:

- Competitive pricing

- Flexibility - from prototypes to full production runs

- Short lead times

- High volume capacity

Alcobra is a turn-key manufacturing facility that can handle any size order–big or small! We offer superior flexibility and are capable of processing numerous metals including:

- Aluminum

- Stainless Steel

- Titanium

- Brass

- Copper

- Steel

And many more.

CNC Machine Specs

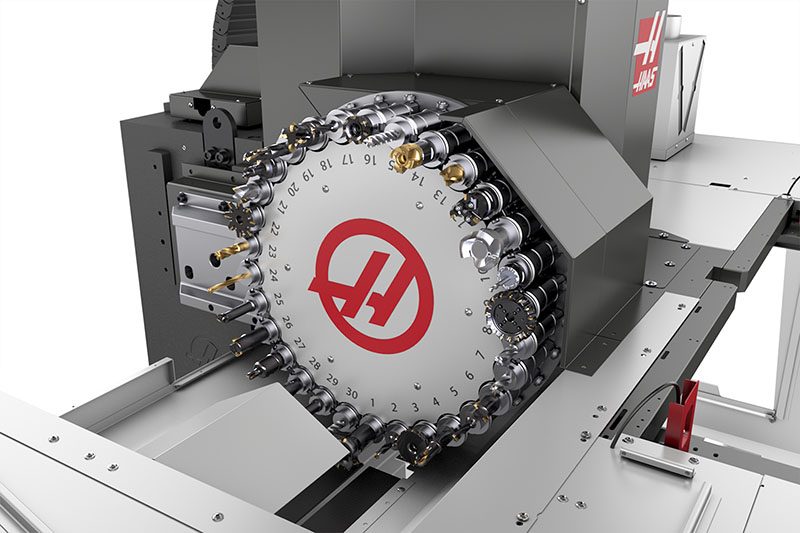

We’ve invested in industry leading equipment to provide you with a wide range of precision CNC machining services. Our CNC machine lineup:

CNC Lathe: Haas ST-30

High-performance turning center designed to provide setup flexibility, extreme rigidity, and high thermal stability. Our attached bar feeder and part catching system makes this an excellent production machine capable of producing a high volume quickly and accurately.

Specs:

- X Axis: 12.5 in

- Z Axis: 26.0 in

- 3″ bar capacity

- Max Rating: 30.0 hp

- Max Speed: 3400 rpm

- Number of Tools: 12-Station BOT

- Bar feeder and parts catching system

CNC Mill: Haas VF5

High-performance turning center designed to provide setup flexibility, extreme rigidity, and high thermal stability. Our attached bar feeder and part catching system makes this an excellent production machine capable of producing a high volume quickly and accurately.

Specs:

- X Axis: 56.0 in

- Y Axis: 26.0 in

- Z Axis: 25.0 in

- Max Speed: 8100 rpm

- Max Torque: 90 ft-lbf @ 2000 rpm

CNC Mill: Haas TM-3

A versatile machine with excellent reliability and performance. Its functionality and simplicity combined with its power and flexibility of the CNC controls make this a perfect machine for use in small quantity or production runs.

Specs:

- X Axis: 40.0 in

- Y Axis: 20.0 in

- Z Axis: 16.0 in

- Max Speed: 4000 rpm

- Max Torque: 33 ft-lbf @ 1200 rpm