Laser Cutting

Are you constantly racing against time to finish your projects on schedule? At Alcobra Metals, our CNC laser cutting ensures reliable production of your custom-cut parts, custom-cut sheet metal, or other metal pieces for your unique application.

We offer industrial laser cutting services for custom metal fabrication of all sizes. No order is too big or too small. Plus, we promise you’ll be impressed with the quality, speed, and cost-effectiveness of our laser cutting services.

CNC Laser Cutter

Laser cutting uses CNC technology to create precise, custom cuts from metals, plastics, and other materials. As its name suggests, laser cutting employs a high-focus laser beam to melt or burn through materials. This results in smooth, highly meticulous, and intricate cuts.

CNC laser cutting also benefits from using harder metals that can withstand other cutting methods. It is a highly efficient and accurate process that allows for a higher production volume in less time. Plus, there is no need to worry about the warping and imperfections of traditional cutting.

Why Choose Alcobra Metals for Laser Cutting?

Extended Life Structure

Our advanced laser cutting technology ensures consistent power with minimized downtown by isolating issues from a single diode. Unlike conventional laser cutters, where multiple diodes can fail at once, our laser source produces high-quality parts from various materials with fewer service interventions.

Beam Cleaning

Our advanced laser cutting technology enables precise N2 cutting of pure copper. This form of beam cleaning in our machines, such as the GX-F series, prevents metal oxidation and ensures a flawless surface finish at the same. It reduces prep time before welding and enhances overall material quality with every cut.

Beam Shaping

Through beam shaping, our laser cutting ensures versatile cutting techniques and applications. By shaping the beam from the generator rather than from the laser cutting head, we provide diverse shapes, sizes, and power distributions. This flexibility in laser cutting makes diverse designs for custom metal fabrication possible.

AI Nozzle Monitoring

Our AI-assisted nozzle optimizes cutting paths by analyzing complex patterns and determining the most efficient cutting sequences. It also maximizes material use by adjusting cutting speed and laser power based on real-time sensor feedback.

Augmented Reality

Our machines’ AR tools have a drag-and-drop interface for intuitive use. They allow you to seamlessly integrate designs within products or materials. With this technology, you can reduce waste and optimally use each material.

Dynamic Drive Control

Our laser cutting machines give operators manual control over acceleration and deceleration speeds. We fulfill your cut designs to a T by using speed to influence the cut’s depth, quality, and overall appearance.

AGR-ECO Technology

Our AGR-ECO system significantly reduces nitrogen consumption by up to 77%—making laser cutting more efficient and cost-effective. With non-contact nozzle technology, consumables last longer.

Remote 360

Our custom part production is monitored with real-time data. Our Remote 360 system allows project managers to track progress, manage workflow, and ensure top-quality laser-cut metal parts across various industries and applications.

What material can a laser cutter cut?

Aluminum Laser Cutting

Aluminum is one of the most popular and versatile metals available. It is highly valued for its low weight, corrosive resistance, recyclability, and electrical and thermal conductivity. Aluminum is also easy to cast into a number of shapes, such as flat bar, angle, channel, plate, and tubing. Because of this wide range of characteristics, it is used in numerous industries, such as aerospace, military, and automotive.

Stainless Steel Laser Cutting

Stainless steel offers huge advantages in corrosion resistance, fire and heat resistance, impact resistance, and sanitation. It is also easy to fabricate and relatively easy to weld, form, and machine. Stainless steel is used extensively in applications requiring sanitary or clean room environments. It is popular in the agriculture, food service, military, and aerospace industries.

Carbon Steel Laser Cutting

One of the oldest, most widely used metals is carbon steel. It is easy and cheap to produce, offers high durability, and is very easy to weld and fabricate with. Today, many grades of carbon steel are available for a wide variety of applications. Everything from skyscrapers to nuts and bolts is made from a grade of steel that has been perfected over time.

Bronze Laser Cutting

Bronze starts as copper and is mixed with other alloys, such as tin, to produce a harder alloy ideal for manufacturing bearings, bushings, wear plates, and parts requiring greater heat and electrical conductivity. It is also easy to machine, making it even more popular among machinists looking to make robust parts that will last after many years of constant use.

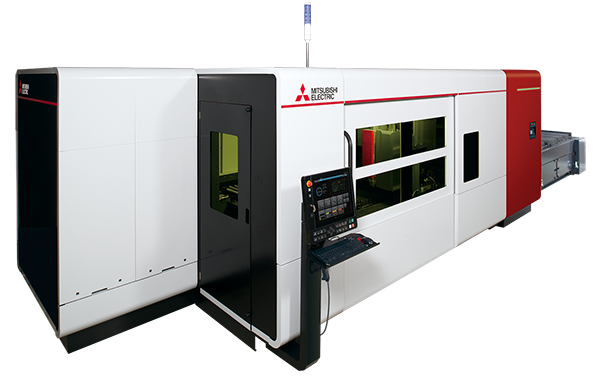

Mitsubishi 3015 GX-F60

With the latest in AI and gas reduction technology, the GX-F Advanced Series of two-dimensional fiber optic lasers delivers more power while using as much as 77% less nitrogen than traditional models. These machines offer superior quality at lightning-fast cut speeds.

Beam kerf: .004″

Travel method: X & Y axis beam

Work area: 122″ x 61.5″ x 4.72″

Max thicknesses: 1″ mild steel, 3/4″ stainless steel, 1/2″ aluminum

Oscillator: Mitsubishi Advanced Fiber Laser Oscillator (6000 watts)

Shuttle table: 2000 lb. maximum weight

Amada FO 3015 M2 NT

The FO 3015 M2 NT is engineered to meet today’s fabricating companies’ high-quality and shorter lead time demands. Features include Fanuc’s new AMADA tuned oscillator and spatter-free pierce for higher-quality piercing in thicker material.

Beam kerf: .004″

Travel method: X & Y axis beam

Work area: 121″ x 61″ x 7.87″

Max thicknesses: 5/8″ mild steel, 1/2″ stainless steel, 3/8″ aluminum

Oscillator: AF400iB (4000 watts)

Shuttle table: 2000 lb. maximum weight

How to Get Started With Your Laser Cutting Design and Materials

Getting started with our laser cutting services is simple and hassle-free.

1.

Contact us for your product order for which you need a custom laser cut for your project. No order is too small. We accept all orders, be they a singular piece or bulk.

2.

We'll provide clear instructions on how to send us your design file and in what format for precision and accuracy in your final laser-cut parts.

3.

Once confirmed, we'll process your order and deliver it within the agreed timeline so you can keep your project on track without delays.