A Short Guide to T304 T303 T316 Stainless Steel Alloys

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

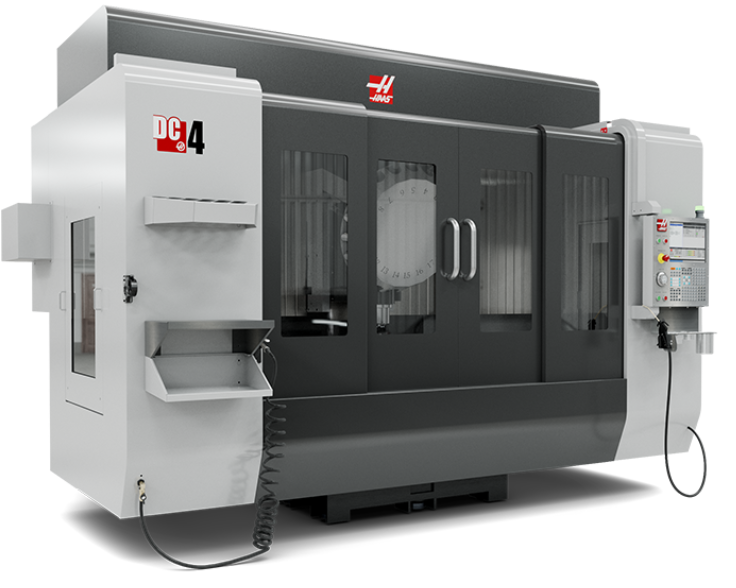

We’re thrilled to announce a game-changing addition to our machine shop: the Haas DC-4/40 Drill Center equipped with a 12,000 rpm spindle. This cutting-edge CNC machine will revolutionize our production capabilities, reduce lead times, and elevate the quality of our machine shop. Read on for a few details about how this investment enhances our operations and what it means for our customers.

The Haas DC-4/40 is a gantry-style drill/tap machine designed for high-speed, high-precision machining. With an impressive 98.4″ X-axis travel, it’s ideal for processing long, narrow parts or high-density production setups. The machine’s 12,000 rpm 40-taper spindle delivers 48% faster cycle times compared to standard 8,100 rpm spindles, ensuring quicker turnaround without compromising torque or power. Its high-speed turret-style tool changer, with a capacity for 20 tools, minimizes cut-to-cut times, streamlining workflows.

This versatile machine is perfect for industries like construction, automotive, and aviation, handling parts over 8 feet long and 1.6 feet wide, including extrusions, steel channels, and pipes. This capability aligns perfectly with our commitment to delivering custom metal solutions with speed and precision.

One of the most significant benefits of the Haas DC-4/40 is its ability to slash lead times. The machine’s rapid feed rates of up to 48 m/min across X, Y, and Z axes, combined with a 1.5-second tool-to-tool change, ensure faster production cycles. This means we can process orders more quickly, whether you need a single prototype or high-volume production runs. For our customers, this translates to shorter wait times and faster project completion, helping you stay ahead of deadlines.

The inline direct-drive system and liquid-cooled spindle maintain thermal stability, allowing for consistent performance during extended runs. This reliability reduces downtime, further optimizing our shop’s efficiency. Whether it’s drilling, tapping, or machining complex profiles, the DC-4/40 ensures we deliver on time, every time.

The Haas DC-4/40 expands our machining capabilities significantly. Its large table (102.4″ x 19.7″) and 600 kg load capacity support heavier and larger workpieces. From intricate aerospace components to robust construction parts, this machine handles it all with precision. The high-speed spindle also allows us to work with various materials, including steel, aluminum, and alloys, ensuring versatility for your custom needs.

Additionally, the machine’s Haas control system—a global industry standard—offers intuitive operation and seamless integration with our existing workflows. This enables our team to program complex parts efficiently, ensuring top-tier quality and accuracy.

For our customers, the addition of the Haas DC-4/40 means faster delivery, higher precision, and greater flexibility. Whether you’re a small business needing custom parts or a large manufacturer requiring high-volume production, our upgraded capabilities ensure we meet your specifications with unmatched efficiency.

Ready to experience faster, high-quality machining? Contact Alcobra Metals today to discuss your project needs and see how our new Haas DC-4/40 can bring your ideas to life.

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

As Q4 2025 unfolds, the global metals and steel industry is navigating a landscape of cautious growth amid persistent challenges. For U.S. steel suppliers, this means a pivotal moment to