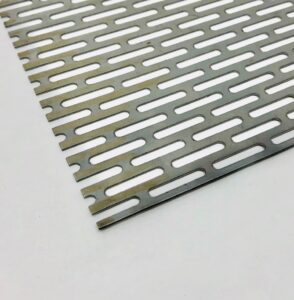

Alcobra offers a variety of steel perforated sheets in standard round hole and decorative patterns that are suitable for a wide variety of applications.

Advantages of Using Carbon Steel for Perforated Sheets

High Tensile Strength

Carbon steel provides significant strength, making these sheets suitable for heavy-duty applications.

Impact Resistance

Can withstand mechanical impacts and harsh conditions, ensuring longevity and reliability in demanding environments.

Versatile Designs

Available in various hole sizes, shapes, and patterns, which can be customized to meet specific functional or aesthetic needs.

Thickness Options

Range of thicknesses to suit different structural requirements, from lightweight applications to heavy-load-bearing uses.

Affordable Material

Generally less expensive than other metals like stainless steel or aluminum while still providing robust performance.

Machinability

Carbon steel sheets are relatively easy to cut, bend, and form, facilitating fabrication processes.

Ease of Installation

Lightweight versions are easy to handle and install, making them practical for large projects.

Perforated Sheet Applications

Industrial Applications

- Common in water treatment plants, food processing, and chemical industries as filters, screens, and sieves to separate solids from liquids or different sizes of particles.

- Employed in HVAC systems, exhaust systems, and air diffusers to allow air to pass through while keeping out debris.

- Used to create noise barriers and soundproofing panels in industrial settings, reducing noise pollution.

Decorative Applications

- Perforated metal is popular in commercial buildings and parking structures for a modern, sleek look while allowing for ventilation and light diffusion.

- Enhances aesthetics in ceilings, wall coverings, partitions, and decorative panels.

- Perforated metal is often incorporated into furniture design for modern, industrial-style tables, chairs, and shelving units.

Safety Applications

- Perforated metal protects operators from moving parts in machinery while allowing visibility and airflow. Common in manufacturing plants.

- Perforated metal sheets are often used as guards in public spaces, sports facilities, and construction sites to provide safety without obstructing views.

- Security fencing for parks, schools, and industrial facilities is usually perforated metal sheets as they can be designed to deter climbing and tampering.