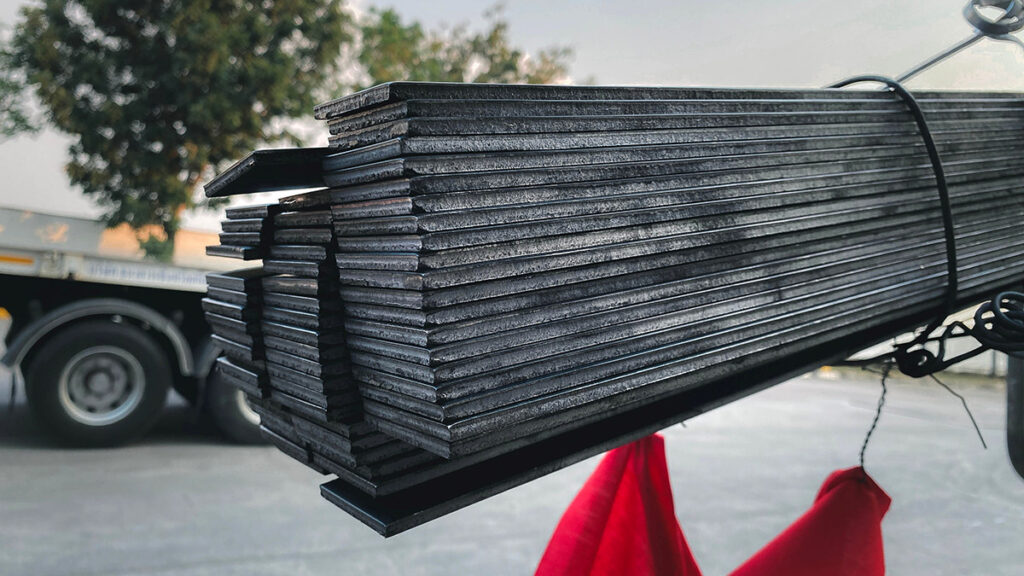

Carbon Steel Rectangular Flat Bar

Carbon steel rectangular flat bars are among the most widely used materials, from building construction to everyday household appliances. With its rectangular cross-section, four flush surfaces, and squared edges, carbon steel flat bars provide stability and support for structural projects.

Carbon Steel Flat Bar Products

Properties of Carbon Steel Rectangular Flat Bar

AISI 1018 and ASTM A36 are both mild or low-carbon steel grades. Because of its low carbon content, it’s highly weldable and machinable. Its high yield strength offers superior load-bearing capabilities compared to traditional steels.

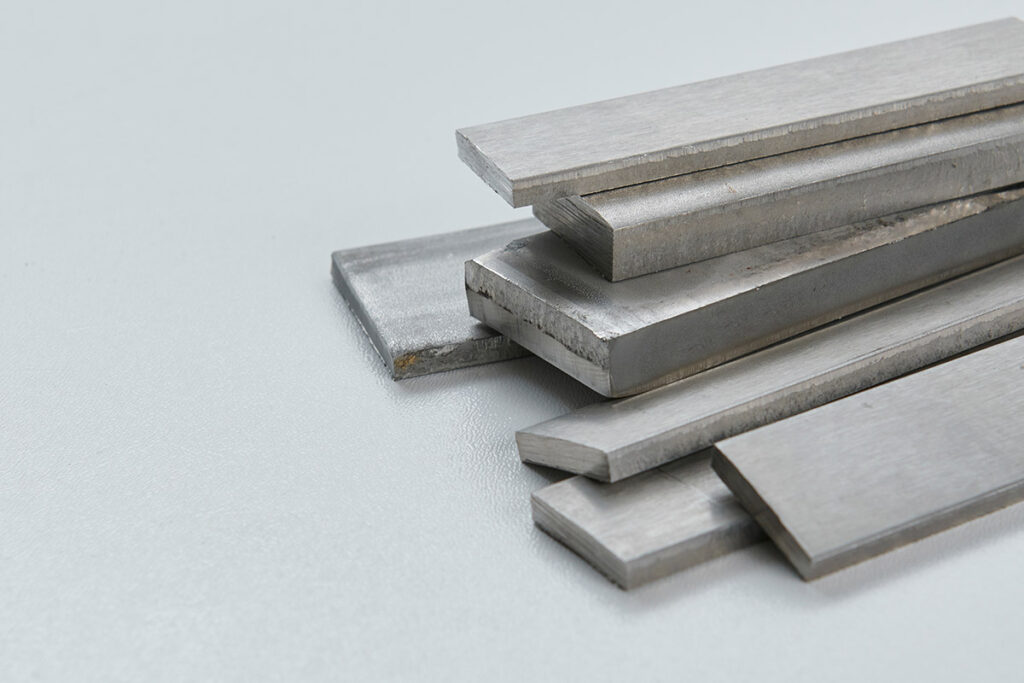

AISI 1018 Cold Rolled Steel Flat Bar

AISI 1018 cold-rolled steel flat bars are precision-engineered through a cold-rolling process following initial hot rolling. This method improves surface finish, enhances dimensional accuracy, and results in tighter tolerances. They are ideal for applications requiring high precision and clean aesthetics.

- Yield Strength: Approximately 53,700 psi

- Surface Finish: Superior to hot rolled due to cold working

- Machinability: Excellent; easy to drill, machine, and fabricate

- Applications: Used in intricate components, fixtures, shafts, and machine parts where dimensional precision and finish are critical

While cold-rolled steel requires more processing, its dimensional stability and visual quality make it suitable for applications where both appearance and tolerance matter.

ASTM A36 Flat Bar (Hot Rolled)

ASTM A36 hot-rolled flat bars are standard mild steel flat bars that offer dependable strength and cost efficiency. Commonly used in general construction, metal fabrication, and heavy-load structural applications, A36 is valued for its versatility and availability.

- Yield Strength: 36,300 psi or higher

- Surface Finish: Rougher surface compared to cold rolled

- Machinability: Good; easy to cut, weld, and form

- Applications: Beams, brackets, support bars, structural plates, and base plates

Because these bars are only hot-rolled, they are more affordable than cold-rolled alternatives. They are best suited to projects where finish is less critical but structural performance is essential.

Applications of Carbon Steel Rectangular Flat Bar

Carbon steel rectangular flat bars are widely used in structural and industrial settings, particularly where corrosion exposure is minimal. With their rectangular cross-section, smooth surface, and strength, these flat bars are ideal for both form and function. Additionally, carbon steel offers excellent machinability, weldability, and load-bearing capacity.

Below are some of the most common applications of carbon steel flat bars across industries:

- Frame Constructions: Steel flat bars are a go-to material for framing due to their ease of cutting, drilling, welding, and bolting. Their rectangular flat profile offers reliable support in structural systems, from building frameworks to warehouse shelving.

- Reinforcements: Used to reinforce beams, walls, and platforms in residential, commercial, and industrial settings. Their durability and adaptability make them essential in supporting and stabilizing existing structures.

- Home Appliances: Mild steel flat bars are used to form parts of home appliances. Their flat, strong design makes them ideal for forming internal supports and brackets.

- Construction Industry: They are often paired with hollow bars to enhance structural strength. Their high versatility allows fabricators to cut them to preferred dimensions and sizes, making them ideal for custom construction applications.

- Mainstream Industrial Projects: Durable and hard-wearing, carbon steel flat bar stock is used in a wide range of industrial applications. Its ability to be riveted, bolted, machined, or welded makes it a flexible choice for demanding, high-stress applications.

National Distributor of Rectangular Steel Flat Bar

As a national supplier of carbon steel rectangular flat bars, Alcobra Metals offers fast, dependable fulfillment for every customer. Place your order before 3 PM PST (Monday–Friday), and we’ll ship within 24 hours via UPS. See our shipping policy for more information.

No Order Too Small! Shop at Alcobra Metals Today

As a national distributor, Alcobra Metals makes it easy to order carbon steel rectangular flat bars online—no quotes, no delays. From single steel flat bars to bulk bar stock, we support projects of every size while staying true to our promise: No order is too small.

Our inventory includes hot-rolled steel flat bars and cold-rolled steel flat bars in a variety of rectangular flat bar sizes. With fast order processing and precision cutting, sourcing rectangular steel has never been more efficient.

Carbon Steel Rectangular Flat Bar FAQs

What is the Hot-rolled Process in Carbon Steel Flat Bars?

The hot-rolled process imparts strength and durability to carbon steel flat bars by forming a billet into a flat rectangular bar using steel shape formers.

What is the Cold-rolled Process in Carbon Steel Flat Bars?

Cold-rolling is the additional re-rolling process applied after hot rolling. It adds strain hardening by rolling them at room temperature, achieving higher precision, greater strength, and better surface finishes.

What is the Difference Between AISI 1018 and ASTM A36 Flat Bars?

AISI 1018 steel flat bars have a better finish but require more labor and costs higher due to the additional cold-rolling process. A36 flat bars are used more in applications that don’t require a great finish and are more cost-effective because they are hot-rolled only.

What is the Melting Temperature of Carbon Steel Flat Bars?

Both AISI 1018 and ASTM A36 steel flat bars have a melting temperature of 1425-1540°C (2600-2800°F).

What is the Density of Carbon Steel?

The density of carbon steel is approximately 0.284 pounds per cubic inch. This makes it easy to estimate weight, shipping requirements, and load capacity.