A Short Guide to T304 T303 T316 Stainless Steel Alloys

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra Metals. These austenitic powerhouses offer top corrosion resistance and versatility. But which one fits your needs? In this guide, we break it down. You’ll learn key properties, top uses, and smart selection tips. Let’s dive in and pick the winner for your work.

Fabricators love T303 for one reason: it machines like a dream. Engineers add sulfur to boost cutting speed. This grade packs 17-19% chromium and 8-10% nickel. As a result, tools glide through it faster than other stainless types.

However, that sulfur tweak slightly dings corrosion resistance. Still, T303 shines in dry or mild settings. Plus, it stays non-magnetic and easy to form.

For example, use T303 in fasteners, gears, and screw machine parts. High-volume shops rely on it for precision without endless tool wear. At Alcobra Metals, we stock T303 rounds in standard sizes as well as metric. Grab some today for your next batch run.

Next up, T304 steals the show as the most versatile pick. It blends 18-20% chromium and 8-10.5% nickel for solid all-around performance. Therefore, it resists rust well in everyday spots, like urban air or light moisture.

What sets T304 apart? Excellent weldability and formability make it a fabricator’s favorite. Additionally, it’s affordable and widely available.

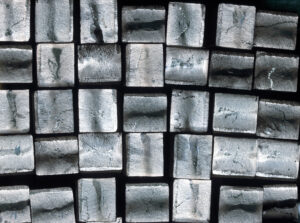

Builders turn to T304 for food processing gear, architectural trim, and auto parts. At Alcobra, our T304 square and round bar waits for your general fab jobs, big and small. Stock up now and keep projects moving.

When environments turn nasty, T316 steps up. It amps corrosion resistance with 2-3% molybdenum alongside 16-18% chromium and 10-14% nickel. This combo fights pitting and chlorides like a champ—perfect for salty seas or chemical baths. In terms of fresh-water applications, T316 is generally overkill but still a great option if you really prefer it.

Moreover, T316 handles higher heat and boasts that reliable 515 MPa strength. It welds and forms well, just like its siblings.

Therefore, marine pros pick T316 for boat fittings and offshore gear. Medical teams use it in implants, too. Chemical plants swear by it for pipes. Alcobra Metals carries T316 ready for harsh-duty demands. Order yours to outlast the competition.

Alloy | Key Elements | Corrosion Resistance | Machinability | Best Uses | Tensile Strength |

|---|---|---|---|---|---|

T303 | Cr (17-19%), Ni (8-10%), Sulfur | Good (mild settings) | Excellent | Fasteners, gears | ~515 MPa |

T304 |

Cr (18-20%), Ni (8-10.5%)

| Excellent | Good | Food, architecture | ~515 MPa |

T316 | Cr (16-18%), Ni (10-14%), Mo (2-3%) | Superior | Good | Marine, medical | ~515 MPa |

Choosing feels easy now, right? First, ask: Do you need top machinability? Go T303. It speeds up production runs. Second, want budget-friendly versatility? T304 covers most bases without breaking the bank.

However, face harsh conditions like salt or acids? T316 protects best. All three resist heat treatment hardening. They also weld smoothly. Always check ASTM A240 specs for quality assurance.

For example, a coastal builder might swap T304 for T316. Therefore, match the alloy to your site’s challenges.

Ready to build stronger? Browse our inventory online. Or chat with our salespeople for specific recommendations.

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

As Q4 2025 unfolds, the global metals and steel industry is navigating a landscape of cautious growth amid persistent challenges. For U.S. steel suppliers, this means a pivotal moment to