A Short Guide to T304 T303 T316 Stainless Steel Alloys

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

Rust, the reddish-brown scourge of metal, occurs when iron or steel is exposed to oxygen and moisture, leading to corrosion. However, not all metals are equally susceptible to this degradation. Here, we delve into four types of metal that are considered “rust-proof”, making them ideal for everything from heavy industry to common household items.

These alloys are: stainless steel, aluminum, copper, and titanium. There are other rust-proof alloys available, but we chose these four because they are the ones we sell the most and are better suited to answering other questions you might have about them.

These alloys are readily available for purchase at our store or website. We strongly encourage you to reach out with other questions about these alloys, their costs, and what applications they are best suited for. We would love to answer any of your questions.

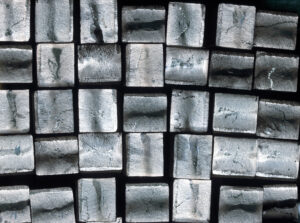

Stainless steel is perhaps the most well-known rust-proof metal. Its resistance to rust comes from its composition, which primarily includes iron, with at least 10.5% chromium. Chromium forms a passive layer of chromium oxide on the surface when exposed to oxygen, which prevents further corrosion.

There are several grades of stainless steel, but 304 and 316 are among the most common. Type 304 is used in a wide range of applications, from kitchen sinks to architectural structures due to its good corrosion resistance and ease of fabrication. Type 316 has an addition of molybdenum, enhancing its resistance to pitting and crevice corrosion in chloride environments, like seawater, making it suitable for marine applications. Both of these stainless alloys are also used in commercial kitchen environments, and are often referred to as “food-grade” stainless steel.

Aluminum is another metal known for its corrosion resistance. Like stainless steel, aluminum develops a protective oxide coating when exposed to air, which acts as a barrier against further oxidization. This self-healing oxide layer means that even if the surface is scratched or damaged, it will naturally repair itself.

Aluminum’s light weight and strength-to-weight ratio make it a favorite in industries ranging from aerospace to packaging. It’s used in everything from aircraft parts to beverage cans. While not immune to corrosion in all environments (like high salinity or acidic conditions), it generally maintains its integrity well in typical atmospheric conditions. And also like stainless steel, it will stand the test of time for decades.

Copper has been used for thousands of years due to its natural resistance to rust. Instead of rusting, copper oxidizes to form a green patina (copper carbonate), which actually protects the metal beneath from further corrosion. This patina is not only functional but also adds aesthetic value, which is why copper is often seen in architectural elements like roofs and statues.

Copper’s excellent conductivity and antimicrobial properties make it invaluable in electrical wiring, plumbing, and even in healthcare settings. It’s worth noting, however, that while copper is mostly rust-proof, it can corrode in certain aggressive environments. This happens particularly where there’s a combination of moisture and other metals.

Titanium is renowned for its extreme strength, low weight, and exceptional corrosion resistance. It forms a very stable oxide layer, much like aluminum, which prevents further corrosion. Titanium is also biocompatible, making it excellent for medical implants where corrosion could have severe consequences.

In industrial applications, titanium is used in marine environments, chemical processing, and aerospace manufacturing. Its resistance to chlorides, acids, and salt water makes it particularly valuable in harsh conditions.

Choosing the right rust-proof metal for your application is crucial. Stainless steel, aluminum, copper, and titanium each offer unique advantages, not just in terms of rust resistance but also in terms of their other physical properties and applications. Selecting the appropriate metal ensures durability and longevity of your product. This also reduces maintenance costs and enhances safety and aesthetic appeal in both practical and artistic contexts.

If you have any questions about choosing the right rust-proof material for your next project, we would love to talk more. Please reach out to us any time.

Stainless steel is used for everything from kitchen gadgets to ocean rigs. Yet, not all grades suit every job. Enter T304, T303, and T316 stainless steel alloys—your go-to options at Alcobra

As Q4 2025 unfolds, the global metals and steel industry is navigating a landscape of cautious growth amid persistent challenges. For U.S. steel suppliers, this means a pivotal moment to